I. Product Overview

As a crucial traffic facility product, the rubber wire tray is specifically designed to protect wires, cables, and other lines. It plays a vital role in various scenarios where vehicle traffic exists and wiring is required. It can effectively prevent lines from being crushed and worn by vehicles, ensuring the safe and stable operation of the lines, while maintaining traffic order and the safety of personnel within the area.

II. Product Features

Excellent Pressure Resistance: Made of high-strength rubber material, it has outstanding compression resistance and can withstand the heavy pressure of vehicles weighing several tons or even dozens of tons. For example, common – specification rubber wire trays can easily withstand the frequent rolling of small cars, medium-sized trucks, and even some heavy-duty engineering vehicles without damage such as cracking or deformation, providing reliable physical protection for the lines.

Good Insulation Performance: Rubber is inherently an excellent insulating material. The rubber wire tray has extremely strong insulation performance and can withstand a voltage of more than 2000V. It can effectively prevent dangerous accidents such as electric leakage and electric shock caused by line breakage, moisture, etc., ensuring the electrical safety of personnel and equipment, especially suitable for places with high requirements for electrical safety.

Waterproof, Moisture-proof, and Corrosion-resistant: The rubber wire tray is waterproof and moisture-proof, and can be used normally in rainy and humid environments without being affected by moisture intrusion. At the same time, it has certain resistance to common corrosive substances such as acids and alkalis. In places such as chemical parks and warehouses where corrosive media may exist, it can also protect the lines stably for a long time, extending the service life of the wire tray and the internal lines.

Convenient Installation and Flexibility: The product is designed with user-friendliness in mind, and the installation is extremely simple, requiring no professional tools or complex construction processes. Generally, it only needs to be placed along the wiring path, the upper cover is opened to put in the cables, and then the cover is closed. In addition, some rubber wire trays adopt a modular design, which can be flexibly combined with different numbers and specifications of wire trays according to the actual wiring requirements, adapting to various complex wiring scenarios.

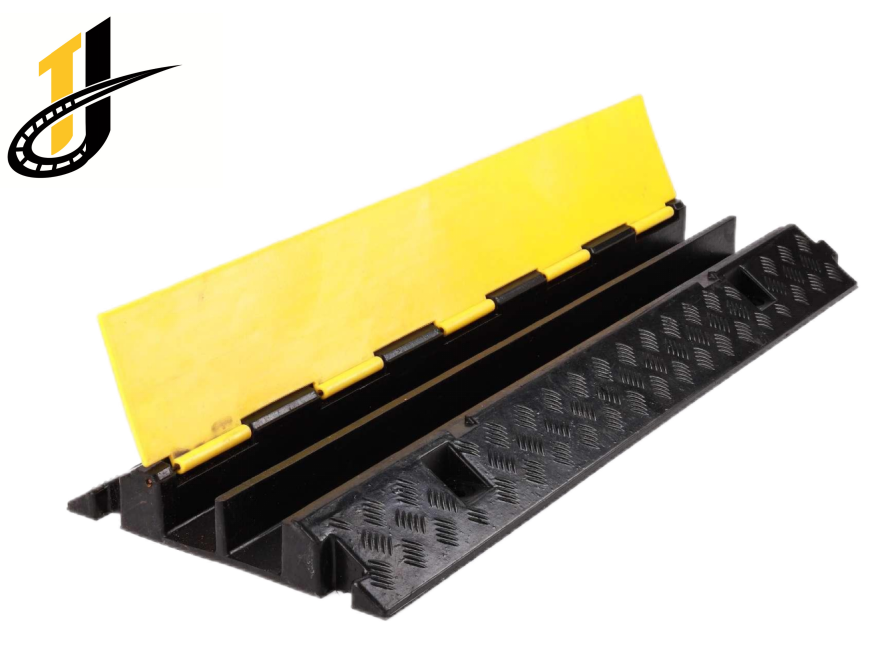

Eye-catching Identification and Anti-slip Design: The surface of the wire tray is generally painted with eye-catching yellow and black colors, which have high visibility both during the day and at night. It can effectively remind drivers to avoid the wire tray and prevent vehicles from accidentally running over it. At the same time, the surface of the wire tray is provided with anti-slip textures. Even in adverse weather conditions such as wet and icy conditions, it can increase the friction with the vehicle tires, avoid vehicle skidding, and ensure driving safety.

III. Product Specifications

Rubber wire trays are available in a wide variety of specifications to meet the wiring needs of different scenarios:

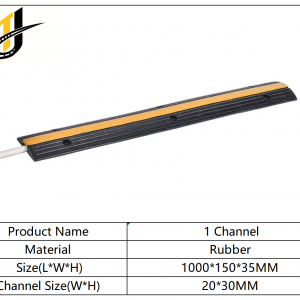

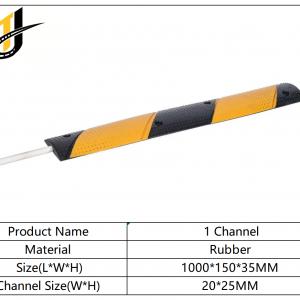

Single-channel Wire Tray: Common specifications are, for example, 1000mm×220mm×30mm (length×width×height), with a channel diameter of 20mm×70mm. It is lightweight and portable, suitable for the protection of a small number of wires and cables, and is often used in scenarios such as small – stage lighting wiring and temporary line protection at home.

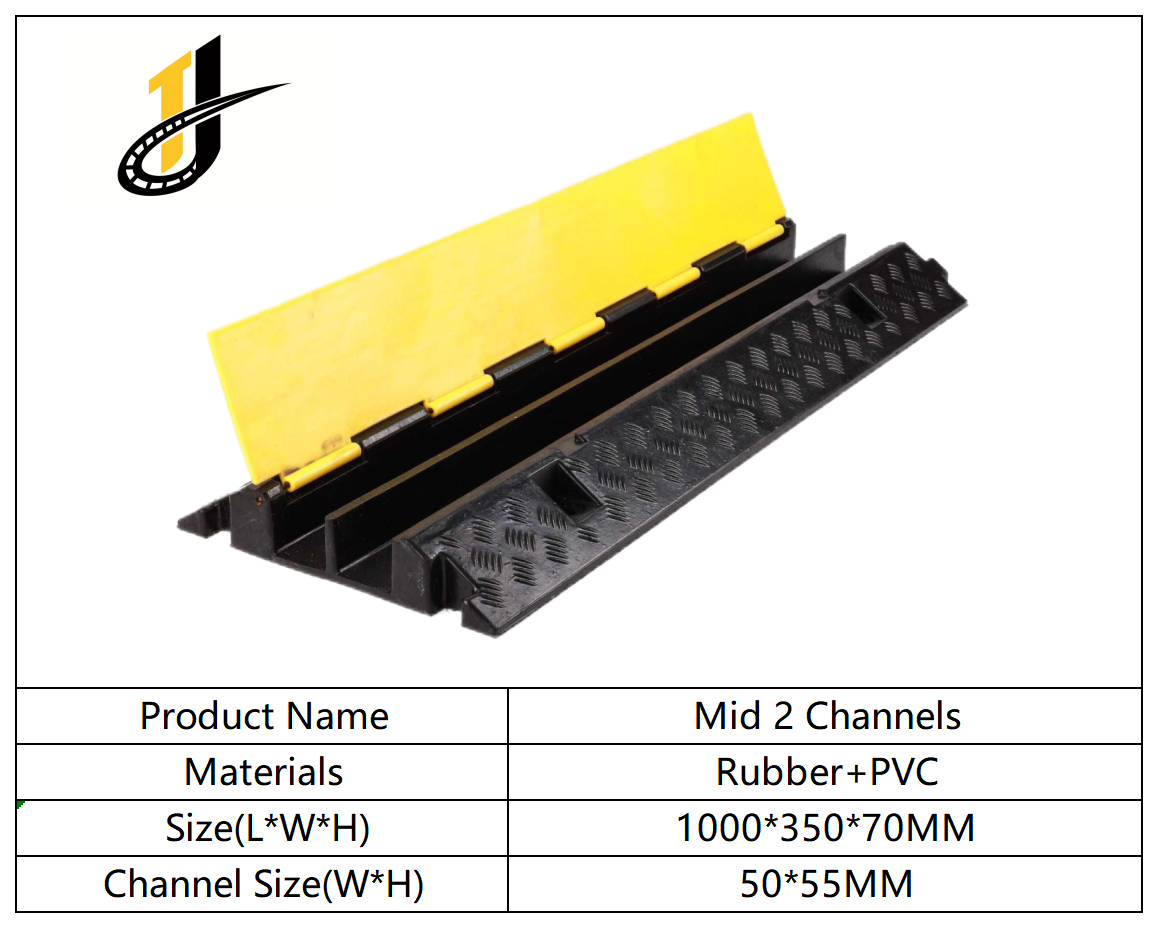

Two-channel Wire Tray: For example, a product with a specification of 1000mm×250mm×50mm has a channel diameter of 32mm×35mm; there is also a large two-channel wire tray with a specification of 900mm×580mm×90mm, with a channel diameter of 80mm×95mm. The two-channel wire tray can accommodate cables of different types or purposes at the same time, and is suitable for comprehensive wiring in places such as shopping malls and office buildings.

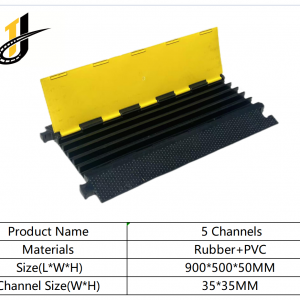

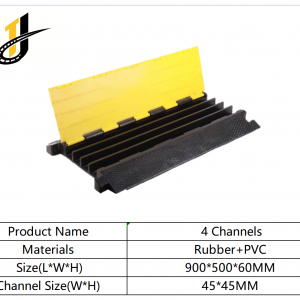

Multi-channel Wire Tray: Three-channel specifications include 1000mm×300mm×50mm (channel diameter 35mm×32mm), 900mm×500mm×85mm (channel diameter 70mm×65mm); four-channel specifications such as 900mm×500mm×60mm (channel diameter 40mm×45mm); five-channel specifications 900mm×500mm×50mm (channel diameter 30mm×40mm), etc. Multi-channel wire trays can meet the protection needs of large-scale concentrated cable laying, and are often used in areas with a large number of lines, such as factory workshops and exhibition halls.

IV. Application Scenarios

Commercial and Office Places: In the parking lots of shopping malls, hotels, and office buildings, during line renovation, equipment installation, or when holding events, temporary or long-term wiring is required. Rubber wire trays can protect wires and cables from being crushed and damaged by vehicles, without affecting the normal use of the parking lot, ensuring the safety and smooth operation of commercial activities.

Cultural and Entertainment Venues: In areas such as stages, studios, exhibition halls, large performance centers, and sports stadiums, when holding performances, exhibitions, competitions, and other events, a large number of electrical, lighting, and audio equipment are needed, involving many line connections. Rubber wire trays can effectively organize and protect these lines, ensuring the smooth progress of the events, and at the same time, avoid accidents caused by audiences, actors, and other personnel stepping on the lines.

Industrial Production Areas: In factory workshops, industrial vehicles such as forklifts and trucks shuttle frequently, and there are a large number of electrical equipment and wiring. Rubber wire trays can be used to protect power cables, control cables, etc. in the workshop, preventing them from being crushed and collided by vehicles, ensuring the stable power supply for industrial production, and reducing production stoppages caused by line failures.

Community and Public Places: In the parking lots of residential communities, property maintenance construction areas, as well as public places such as government agencies, schools, and hospitals, when carrying out line laying, equipment maintenance, and other operations, using rubber wire trays can not only protect the lines but also ensure the safety of personnel and vehicle traffic, maintaining the normal order of the place.

If you have other ideas about the content of the product introduction, such as adding or reducing specific function descriptions, adjusting the language style, etc., you are welcome to let me know at any time.